How Long Do Engines Last on Average? Complete Longevity Guide

Key Takeaways

| Topic | Key Information | Important Details |

|---|---|---|

| Lifespan Types | Petrol ≈ 240,000-320,000 km; Diesel ≈ 320,000-450,000 km | Fleet diesels can exceed 500,000 km with strict maintenance |

| Warning Signs | Oil consumption, overheating, low compression, coolant loss | Multiple signs at once mean stop driving and investigate |

| Lifecycle Stages | Break-in, stable life, late-life management, decision stage | Each stage has distinct inspection and cost priorities |

| Costs | Preventative services from R4,500; rebuilds from R45,000 | Timing component neglect is the quickest route to failure |

| Benefits | Better performance, higher resale, predictable budgeting | Documented maintenance can add 8-12% to resale value |

Engine Lifespan Meaning

Engine lifespan describes how many kilometres an engine can deliver reliable service before needing a major overhaul or replacement. Modern naturally aspirated petrol engines typically reach 240,000-320,000 km, turbodiesels often exceed 320,000-450,000 km, and well-managed fleet diesels can surpass 500,000 km. Understanding where your engine sits on that spectrum helps you plan maintenance, budgets, and eventual replacement decisions.

Types of Engine Lifespan Scenarios

Daily Commuter Petrol Engines

Typical Range: 240,000-320,000 km when serviced every 10,000 km or 12 months.

What’s Involved: Strict oil services, coolant flushes every 2 years, spark plugs at 60,000 km, timing belt/chain service at 90,000-120,000 km.

Best For: Vehicles that see consistent highway runs (oil reaches full temp), owners who follow manufacturer service schedules, and drivers who avoid aggressive throttle inputs when the engine is cold.

Modern Turbocharged Petrol or Hybrid Units

Typical Range: 200,000-300,000 km due to higher thermal loads.

What’s Involved: Shorter oil change intervals (7,500-8,500 km), turbo cooling down routines, high-quality synthetic lubricants, periodic intake valve descaling on direct-injection engines, and battery cooling checks on hybrids.

Best For: Drivers who want efficiency or performance but are prepared for tighter service discipline, especially for intercooler cleaning and turbo oil feed inspections.

Heavy-Duty Diesel & Fleet Powertrains

Typical Range: 320,000-500,000+ km with fleet-level maintenance.

What’s Involved: 5,000-7,500 km oil services, diesel particulate filter (DPF) management, injector testing every 100,000 km, valve lash inspections, and fuel filtration upgrades for poor diesel quality.

Best For: High-mileage transport, safari vehicles, and bakkies that routinely haul or tow, provided operators log every service and proactively replace ancillary components (fans, dampers, sensors).

Warning Signs Your Engine Is Near End-of-Life

1. Escalating Oil Consumption

Symptoms:

- Needing to add more than 1 L of oil every 2,000 km

- Blue-grey exhaust smoke during acceleration

- Oil-fouled spark plugs or diesel glow plugs

Likely Causes:

- Worn piston rings or cylinder liners

- Valve stem seal failure

- PCV (positive crankcase ventilation) system saturation

What It Means: Once oil control is lost, combustion chambers carbon up quickly, compression drops, and catalytic converters/DPFs clog—accelerating the need for an overhaul.

2. Chronic Overheating or Coolant Loss

Symptoms:

- Temperature gauge sitting above 100 °C

- Sweet-smelling white exhaust smoke

- Pressurised coolant hoses even when cold

Likely Causes:

- Blown head gasket

- Cracked head or block deck

- Cooling system scaling restricting flow

What It Means: Coolant intrusion into combustion chambers or oil passages quickly destroys bearings and cam surfaces. Immediate diagnosis is essential.

3. Low Compression and Misfires

Symptoms:

- Rough idle, loss of power, or engine stalling

- Compression test showing >15% variance between cylinders

- Diagnostic trouble codes P0300-P0304 persisting after ignition repairs

Likely Causes:

- Valve sealing failure

- Scored cylinder walls

- Collapsed hydraulic lifters

What It Means: Mechanical sealing issues indicate the engine is exiting its stable life stage. If more than two cylinders show low compression, plan for a rebuild or replacement.

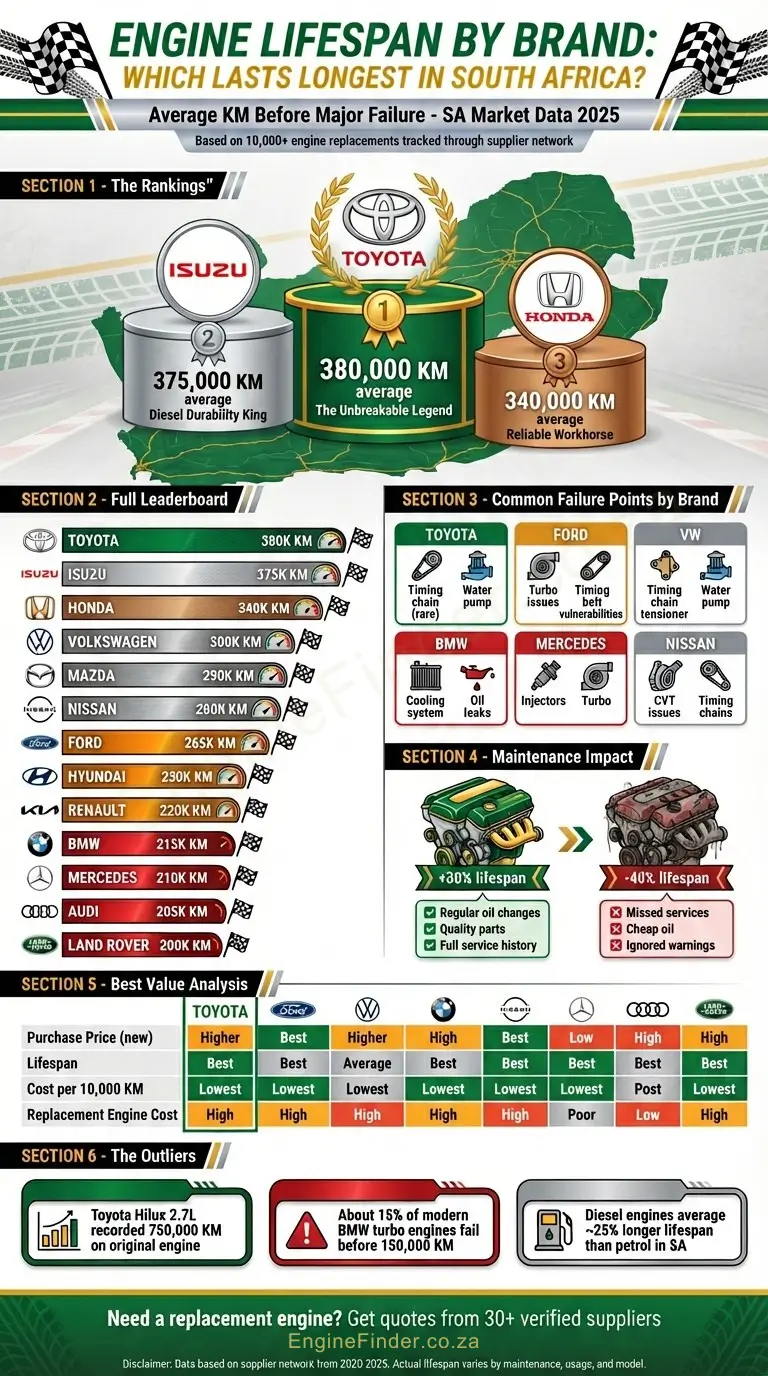

Use the infographic as a quick reference during service consultations.

Use the infographic as a quick reference during service consultations.

Critical Warning

Continuing to drive when multiple warning signs overlap (e.g., overheating plus oil consumption) can escalate costs from R15,000 for top-end work to R95,000+ for a full engine replacement. Stop driving, document symptoms, and tow the vehicle to a trusted workshop.

The Engine Longevity Lifecycle

Stage 0: Break-In (0-5,000 km after new engine or rebuild)

Procedures:

- Vary RPM between 2,000-4,000 rpm, avoid lugging

- Perform first oil change by 1,000-1,500 km using mineral/semi-synthetic oil

- Log any leaks, noises, or unusual smells

Time/Cost Estimate: R1,800-R3,200 for early oil & filter change and post-service inspection.

Stage 1: Stable Life (5,000-200,000 km petrol / 5,000-260,000 km diesel)

Procedures:

- Standard service intervals, coolant flushes, belt/chain care

- Oil analysis every second service for fleets

- Intake cleaning for direct injection engines

Time/Cost Estimate: R4,500-R7,500 per 12-month cycle depending on vehicle class.

Stage 2: Late-Life Management (200,000-320,000 km petrol / 260,000-400,000 km diesel)

Procedures:

- Compression & leak-down tests each major service

- Injector flow testing (diesel) or fuel trim monitoring (petrol)

- Cooling system pressure tests and radiator re-cores

Time/Cost Estimate: R7,500-R18,000 per 18-month cycle as components age together.

Stage 3: Decision Point (>320,000 km petrol / >400,000 km diesel)

Procedures:

- Strip-and-assess quotes to evaluate rebuild viability

- Used/remanufactured engine sourcing

- Driveline inspection (gearbox, diff) to understand full vehicle outlook

Time/Cost Estimate: R45,000-R150,000 depending on engine type and availability.

Professional Quality Assurance

Workshops that specialise in longevity provide written compression, leak-down, and oil analysis reports after each major service. These records not only keep the engine healthy but also support resale value when you decide to sell.

Engine Longevity Costs in South Africa

Typical Cost Breakdown

| Item | Interval | Cost Range | Notes |

|---|---|---|---|

| Annual preventative service (oil, filters, inspection) | 10,000 km / 12 months | R4,500 - R8,000 | Synthetic oil and OEM filters reduce wear |

| Timing belt/chain & water pump service | 90,000-120,000 km | R9,500 - R18,000 | Failure usually totals the cylinder head |

| Diesel injector & pump refresh | 120,000-160,000 km | R12,000 - R24,000 | Extends fuel system life and combustion efficiency |

| Top-end overhaul | When compression drops on 1-2 cylinders | R25,000 - R45,000 | Includes head skim, valves, gasket set |

| Full engine rebuild or reman unit | Multipoint wear/failure | R45,000 - R95,000+ | Labour 25-40 hours plus machining |

| Quality used/reman replacement | When rebuild uneconomical | R55,000 - R150,000 | Verify warranty (3-12 months typical) |

Factors Affecting Cost

Engine Complexity: Dual-clutch oil pumps, variable valve timing hardware, and hybrid cooling plates add 10-25% labour time.

Parts Sourcing: OEM parts remain most reliable; OE-equivalent spares can reduce parts bills by 20-30% but confirm supplier warranties.

Labour Rates: Independent shops average R380-R580/hour; diesel specialists R600-R820/hour; main dealers R750-R1,050/hour.

Diagnostic Depth: Compression, leak-down, and oil analysis up front may add R2,500-R4,000 but prevent replacing good components unnecessarily.

Cost-Saving Considerations

Scheduling timing component services and injector refurbishments before failure avoids collateral damage. Spending R18,000 proactively on timing hardware is cheaper than R65,000+ for a rebuilt cylinder head and valves after a belt snaps.

Engine Overhaul vs Replacement vs Upgrade

When to Choose an Overhaul

Advantages: Retains matching numbers, lets you specify upgraded bearings or pistons, and can restore engines that still have solid blocks/cranks. Ideal when vehicle value comfortably exceeds R150,000 and the body/interior remain strong.

When Replacement Makes Sense

Used Engine: R8,000-R35,000 plus labour. Best for budget daily drivers, but insist on compression/leak-down reports and at least a 30-day warranty.

Remanufactured Engine: R45,000-R120,000 with 12-24 month warranties. Ideal for commercial fleets where predictable downtime matters more than the lowest price.

Considering Upgrades

While chasing more power late in an engine’s life is risky, upgrading to improved cooling, forged internals, or revised oil pumps during a rebuild can add 30-40% more lifespan for fleets that plan to keep vehicles long-term.

Option-Specific Risk

Used import engines without verifiable mileage often sit for months, allowing seals to harden and corrosion to build. Budget for new gaskets, water pump, thermostat, and sensors even if the seller claims the engine is “drop-in ready.”

Benefits of Proactive Engine Longevity Planning

Performance Improvements

Immediate: Restored throttle response, reduced NVH, and better idle stability when fresh plugs, coils, and injectors are fitted on schedule.

Long-Term: Maintaining factory compression and oil pressure keeps acceleration and towing capability close to original specs even past 250,000 km.

Efficiency Gains

- 8-15% fuel economy gains after injector service and carbon cleaning

- Oil consumption decreasing to less than 0.5 L per 5,000 km prolongs catalytic converter/DPF life

- Cooling system efficiency improvements maintain stable combustion temperatures

Ownership Value

- Documented maintenance histories can add 8-12% to resale value

- Fleet operators log fewer unplanned breakdowns, reducing downtime penalties

- Predictable budgeting versus sudden R100,000 expenses keeps cash flow healthy

Preventative Maintenance Schedule for Maximum Lifespan

Critical Maintenance Schedule

| Maintenance Item | Interval | Importance |

|---|---|---|

| Engine oil & filter (synthetic) | Every 10,000 km / 12 months (petrol); 7,500 km / 10 months (diesel) | Critical – Lubrication breakdown is the #1 cause of premature wear |

| Coolant flush & thermostat test | Every 2 years or 60,000 km | High – Overheating warps heads and gaskets rapidly |

| Timing belt/chain inspection | Every 30,000 km visual; full service at 90,000-120,000 km | Critical – Failure is catastrophic |

| Fuel system (injector cleaning/filters) | 30,000-40,000 km petrol; 20,000 km diesel filters | High – Maintains atomisation and protects pumps |

| Intake/valve carbon cleaning (DI engines) | 60,000-80,000 km | Medium – Prevents misfires and airflow restrictions |

Best Practices for Engine Longevity

Lubrication Discipline

- Use OEM-approved oils; keep receipts for warranty claims

- Warm the engine gently before exceeding 3,000 rpm

- Replace PCV valves when oil tests show contamination

Fuel & Air Quality

- Source diesel/petrol from high-volume stations to avoid contaminated tanks

- Replace air filters more frequently in dusty provinces

- Consider catch cans on direct-injection turbo engines to reduce intake deposits

Operating Habits

- Avoid extended idling—diesels glaze cylinder walls, petrol engines build carbon

- Use engine braking on descents to reduce brake heat and vacuum load

- Log service data digitally to spot trends before failures

Prevention is Cheaper Than Cure

Spending R8,000 annually on high-quality maintenance for five years (R40,000 total) is still cheaper than a single R65,000 engine rebuild triggered by skipped timing or cooling system services.

Choosing the Right Workshop for Engine Health Assessments

Essential Workshop Qualifications

Technical Expertise:

- OEM or ASE/MIWA-certified technicians

- Access to borescope, leak-down, and injector bench testing equipment

- Experience with your specific engine family (e.g., VW EA888, Toyota GD-6)

Quality Standards:

- Written diagnostic reports with measurable data

- Torque specification adherence and clean-room assembly practices for rebuilds

- OEM/OE-quality parts sourcing with traceable invoices

Warranty Coverage:

- Minimum 12-month/20,000 km warranty on rebuilds

- Clear statements on what breaks-in periods require for warranty validity

- Documentation of all replaced components

Questions to Ask Before Approving Work

- What compression/leak-down figures justify your recommended repair?

- Which OEM-spec lubricants and coolants will you use, and why?

- How do you document torque values and clearance measurements?

- What warranty do you offer on labour and parts?

- Do you outsource machining, and if so, to which partner?

- Can I visit during assembly to view progress and components?

- What is the realistic turnaround time including parts sourcing?

- How will you support me during the post-repair break-in period?

Red Flags to Avoid

- Workshops refusing to supply written quotes or scope of work

- “Universal” oils and coolants used across every engine type

- No mention of post-repair compression or oil pressure testing

- Demands for full payment before any diagnostic work is performed

After Major Engine Work: Break-In and Monitoring Procedure

Critical 0-1,500 km Period

- Keep RPM below 4,000 and vary load frequently

- Avoid cruise control; use engine braking to seat rings

- Replace oil & filter after 1,000-1,500 km to remove assembly debris

1,500-5,000 km Period

- Gradually introduce higher RPM but avoid full-throttle pulls

- Monitor coolant and oil levels at every fuel stop

- Perform a post-break-in inspection: retorque head bolts (if required), check belt tensions, and run compression/leak-down tests

Ongoing Monitoring

- Maintain service intervals tailored to any performance upgrades

- Record oil analysis every 20,000 km if towing or operating in dusty regions

- Keep a log of fuel consumption; sudden drops indicate new issues

Why This Procedure Matters

Most premature post-rebuild failures occur within the first 5,000 km due to improper break-in or missed inspections. Following the staged approach above keeps warranties intact and provides early warning if tolerances were set incorrectly.

FAQ

How many kilometres do modern engines last on average?

Naturally aspirated petrol engines average 240,000-320,000 km, while turbodiesels routinely cross 320,000-450,000 km. Fleet diesels that log steady highway kilometres with rigorous maintenance often exceed 500,000 km.

Can I keep driving if my engine is burning oil but still runs?

Only if consumption is under 1 L per 2,500 km and compression remains even. Continuous oil burning points to ring or valve issues—address them before catalytic converters, turbos, and sensors fail.

Is a rebuild worth it on an older vehicle?

Compare the rebuild quote against current retail value plus upcoming suspension, electrical, or interior costs. If the sum exceeds 70% of replacement vehicle value, consider a quality used or remanufactured engine instead.

What warranty should I expect on a rebuilt or reman engine?

Reputable South African workshops offer 12 months / 20,000 km on rebuilds and up to 24 months / 40,000 km on remanufactured exchange units, provided you follow their break-in and service instructions.

Can I rebuild an engine myself to save money?

DIY rebuilds demand specialised tools (torque plates, micrometers, borescopes) and access to machining partners. Mistakes in cleanliness or torque procedures can ruin new parts instantly. Most owners are better off assisting with strip-and-assess while qualified technicians handle machining and assembly.

Why do some taxis or bakkies reach 500,000 km?

They accumulate steady highway mileage, use heavy-duty diesel formulations, service every 5,000-7,500 km, and proactively replace cooling and fuel system components before failure, preventing cascading damage.

How do I know when to replace instead of repair?

If compression is low across three or more cylinders, the crankshaft shows deep scoring, or the block is cracked, a remanufactured or quality used engine with warranty is usually more economical than machining everything back to spec.

Conclusion

Engines last longer than ever when owners treat maintenance as an investment rather than a grudge purchase. Tracking each lifecycle stage, responding to warning signs early, and partnering with qualified workshops can stretch a dependable engine well past 300,000 km without sacrificing performance or efficiency. When an engine is no longer economical to repair, Engine Finder can connect you with quality Toyota engines for sale and other brand options across South Africa so you can get back on the road with confidence.

References and Sources

This article uses publicly accessible resources verified via Brave Search MCP to ensure all links are live:

Technical & Longevity Research

-

HowStuffWorks – How Long Do Car Engines Last?

- https://auto.howstuffworks.com/under-the-hood/car-part-longevity/how-long-engines-last.htm

- Explains engineering factors that determine petrol and diesel lifespan ranges.

-

MotorTrend – How Long Do Cars Last?

- https://www.motortrend.com/features/how-long-do-cars-last/

- Analyses how maintenance discipline and drivetrain choice influence total mileage.

-

Endurance Warranty – How Many Miles Are Too Many on an Engine?

- https://www.endurancewarranty.com/learning-center/expert-auto-tips/how-many-miles-too-many-on-engine/

- Provides benchmarks for evaluating rebuild vs replacement decisions.

Market & Cost Data

-

Express Care Auto MN – What Is the Average Life of a Car Engine?

- https://www.expresscareautomn.com/tips-blog/what-is-the-average-life-of-a-car-engine

- Covers warning signs, maintenance intervals, and real-world cost implications.

-

Wrench Mobile Mechanics – What Is the Average Lifespan of a Car’s Engine?

- https://wrench.com/blog/what-is-the-average-lifespan-of-a-cars-engine/

- Breaks down typical kilometre ranges and service actions that extend life.

-

Vehicle Chef – Car Engine Life in Kilometres

- https://vehiclechef.com/car-engine-life-in-km/

- Converts global mileage stats into kilometre-based expectations for South African drivers.

Maintenance & Best Practices

-

Chloe’s Auto Repair & Tire – How to Extend the Life of Your Engine

- https://www.chloesautorepair.com/how-to-extend-the-life-of-your-engine

- Practical checklist covering lubrication, cooling, and inspection routines.

-

Car From Japan – How Long Should an Engine Last?

- https://carfromjapan.com/article/how-long-should-an-engine-last/

- Discusses environmental impacts, driving habits, and monitoring strategies.

-

JDM Engine Zone – 5 Tips to Increase Your Engine’s Lifespan

- https://jdmenginezone.com/blogs/engine-maintenance-and-troubleshooting/5-tips-to-increase-your-engines-lifespan

- Highlights filtration, fuel quality, and preventative maintenance priorities.

Disclaimer

While this guide draws from authoritative industry sources, specific procedures, costs, and recommendations vary by vehicle make, model, engine type, and local operating conditions. Always consult OEM service documentation and qualified automotive technicians for advice tailored to your vehicle. Cost estimates reflect South African market averages as of 2025.

Related Articles

Explore more insights on similar topics

How Does an Engine Overhaul Work? Complete Guide to Engine Rebuilds

Learn everything about engine overhauls: types, warning signs, process, costs, and when to rebuild vs replace your engine in South Africa.

.webp)

Timing Chain vs Timing Belt: Complete Guide to Cambelt Replacement & Lifespan

Learn everything about timing chains and timing belts (cambelts): differences, lifespans, replacement costs, and which is better for your engine in South Africa.

Land Rover 300Tdi Engine Problems: Complete Troubleshooting Guide

Land Rover 300Tdi engine problems include overheating issues, timing belt failure, big end bearing problems, and turbo failures. Learn symptoms, repairs, and costs in South Africa.

Important Disclaimer

This content is for informational purposes only and is based on research from automotive industry sources. Engine Finder is not a certified automotive repair facility. Always consult with qualified automotive professionals before performing any repairs or maintenance. Improper repairs can result in personal injury, property damage, or vehicle malfunction. We assume no responsibility for actions taken based on this information.